A video showing some more modelling is here

http://www.controldraw.co.uk/Movies/BiotechPlant2.html

This shows the development of the model to include BioReactor diagrams, (but not the details, that will follow)

It shows how to create a polymorphic diagram and it instances

Wednesday, 10 February 2010

Sunday, 7 February 2010

Requirements Analysis Progress report

There are so far about 20 people who have expressed interest in following and contributing to this, and many more listening, judging from the number of visitors here.

One person has offered a process, in fact a complete plant!

" The process starts in the cell culture lab where biologicaly engineered cells are taken from a cell bank and grown in lab scale fermentation process until enough cells are produced to seed the first industrial fermentor. Process flow is : cell Culture - Fermentation- Harvest- Recovery- Purification - Freezing. Upstream Area, Midstream Area, and Downstream Area are the main first level of physical models in the two trains. "

Unfortunately there are no P&ID's or process descriptions available, so it is not good basis to proceed with. But some modelling is possible - see

One person has offered a process, in fact a complete plant!

" The process starts in the cell culture lab where biologicaly engineered cells are taken from a cell bank and grown in lab scale fermentation process until enough cells are produced to seed the first industrial fermentor. Process flow is : cell Culture - Fermentation- Harvest- Recovery- Purification - Freezing. Upstream Area, Midstream Area, and Downstream Area are the main first level of physical models in the two trains. "

Unfortunately there are no P&ID's or process descriptions available, so it is not good basis to proceed with. But some modelling is possible - see

Monday, 1 February 2010

A free peer reviewed automation design model for your process!

ControlDraw Ltd proposes to carry out and show online the development of functional requirement of a readers process.

Readers will define the process that will be used.

Readers will contribute by helping to choose which reader’s process we start with, and by reviewing the documents as they develop. This will be done using LinkedIn Groups

The Process

This could be a portion of a process plant, say a couple of process units.It may be batch or continuous

Ideally this will be one that is real and is soon to be automated. Even if you have already started – you might like to use the exercise to compare your own design.

Source information

Please send ,in the first place, a brief (but not too brief) description of your process. You must also be able to supply P&ID’s no more than 3. As this process will be carried out publicly you must accept that anything you send will be published online.

This will of course use ControlDraw, but others (especially those that promote their own methodologies) are invited to do the same using their normal documentation system.

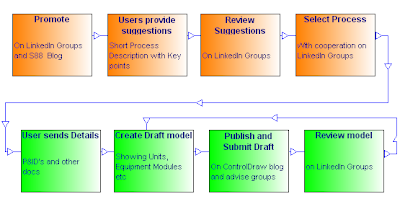

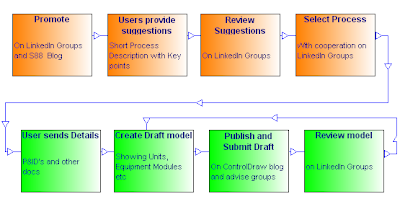

Here is an overview of the plan

Readers will define the process that will be used.

Readers will contribute by helping to choose which reader’s process we start with, and by reviewing the documents as they develop. This will be done using LinkedIn Groups

The Process

This could be a portion of a process plant, say a couple of process units.It may be batch or continuous

Ideally this will be one that is real and is soon to be automated. Even if you have already started – you might like to use the exercise to compare your own design.

Source information

Please send ,in the first place, a brief (but not too brief) description of your process. You must also be able to supply P&ID’s no more than 3. As this process will be carried out publicly you must accept that anything you send will be published online.

This will of course use ControlDraw, but others (especially those that promote their own methodologies) are invited to do the same using their normal documentation system.

Here is an overview of the plan

Subscribe to:

Comments (Atom)